This is a LOVELY picture of Kristina after a long hard morning of poring concrete into our final molds! Thumbs up! We're done.

Alright, whoever said this wasn't messy work? I'm pretty sure we all got pretty dirty at some point when working with the concrete, pouring and mixing.

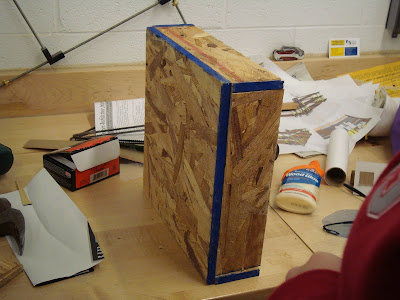

These square molds below are the forms we used for our bases. For our structures we figured out we needed a second piece to hole the structure in place and make it stronger.

Our final casting of the mold of the structure we had to create and it's base. This was a lot of hard, dirty, cold work! We were outside or in the workshop four class days the full three hours of class. It took a lot of time and measurements but we were all very happy with the way our structures turned out. It was fun to finally make something that is actually going to be installed and used for quite some time. I'm happy we'll get to walk by our work everyday and remember all the hard work that went behind it.